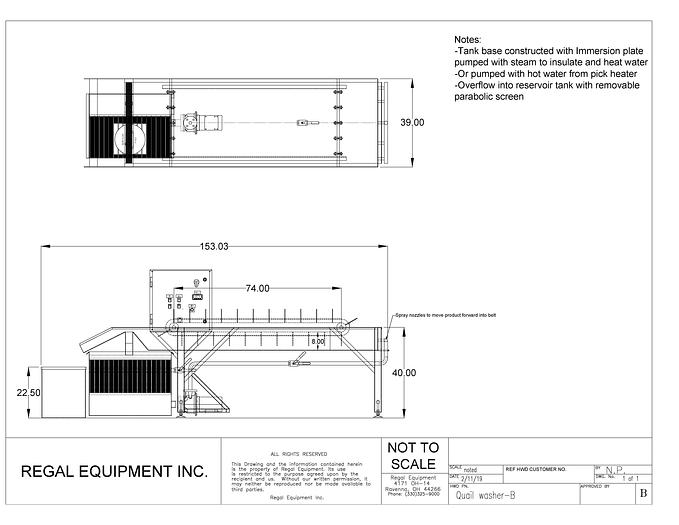

Qual Scald Tank

Qual Scald Tank

Location:Ravenna, OH

Description

Flighted hold down conveyor over shallow washbasin designed for timed product transport. Product dumped from rear by staff is entered into the feed end of the scald tank. Product gets pushed forward by rear jets into the flighted hold down conveyor. This provides for complete submersion of the product and is also on a VFD to control product retention time. System also has a Regenerative blower that pies air into the bottom of the tank this keeps the Quail buoyant and also aids in turbulent washing/coating. Approximate dimensions of Scald Tank cooker to be 48” inches wide X 11’ long. The product then exits cooker onto a perforated decline chute. Water will be circulated in a closed loop circuit with a stainless-steel open impeller pump with sanitary tri-clover quick disconnects. Temperature controlled will be with a digital temp control on panel face. Water will be cleaned up by parabolic screen (qty 2). Inlet/outlet fittings provided for hot water source. Machine will also have a float controlled automatic top off ASCO water valve. Customer to supply all hot water supply and delivery means. Temperature will be displayed electronically. Hold down conveyor is on air cylinders and will pivot out of the way for ease of cleaning system. On leveling feet. Stainless steel and other food grade components.

Insulating Mixing Tank Approx. 500-gallon mixing tank used to batch water and keep it at the required temperature for the process includes valving and RTD

Control panel will be setup for customer to wall mount.

Plumbing will be Tri-Clamp fittings for easy cleaning.

Spray Header will have removable nozzles.

Control system includes:

• NEMA 4X approved SS cabinets and devices

• Illuminated push buttons

• Plotted CAD wiring diagrams

All piping and electrical wiring by customer.

Spare Parts Package Includes: Spare Belt, Bearing Inserts, Pump Rebuild Kit, Spare Nozzles

Specifications

| Manufacturer | Regal Equipment Inc. |

| Condition | New |

| Stock Number | 18280 |